Please contact us if you have any questions, we will be happy to help you 7*24 hours.

Copyright:Jilin Henghua Optoelectronics Co., Ltd.

News HENGHUA OPTOELECTRIC

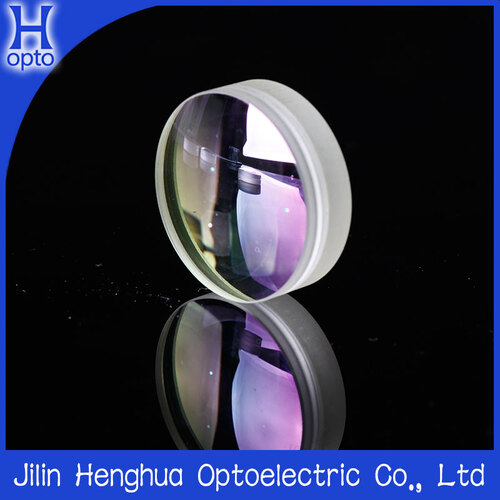

Manufacturing method of the aspheric lens from China

1. Precision polished molding. Grinding and polishing are generally applicable to the occasion of producing a single piece of the aspheric lens from China at one time. With the improvement of technology, its precision is getting higher and higher. Most notably, the precise polishing of the aspheric lens from China is controlled by a computer and automatically adjusted to achieve parameter optimization.

Aspheric lens from China If higher quality polishing is required, magneto-rheological finishing (magneto-rheological finishing) will be used. Magnetorheological polishing offers higher performance and shorter times than standard polishing. Precision polishing requires professional equipment and is the first choice for sample production and small batch samples.

2. Hybrid molding. Hybrid molding, with a spherical lens as the base, die-cast on the surface of the spherical lens through an aspheric mold and use ultraviolet light to cure the aspherical body with a layer of high molecular polymer. Hybrid molding generally uses an achromatic spherical lens as the base, and a layer of aspheric surface is die-cast on the surface to achieve simultaneous elimination of chromatic aberration and spherical aberration. Hybrid molding aspheric lens from China, suitable for occasions requiring additional features (simultaneously eliminating chromatic aberration and spherical aberration) and mass production.

Through the above introduction and analysis of the Manufacturing method of the aspheric lens from China, hope it helps you.